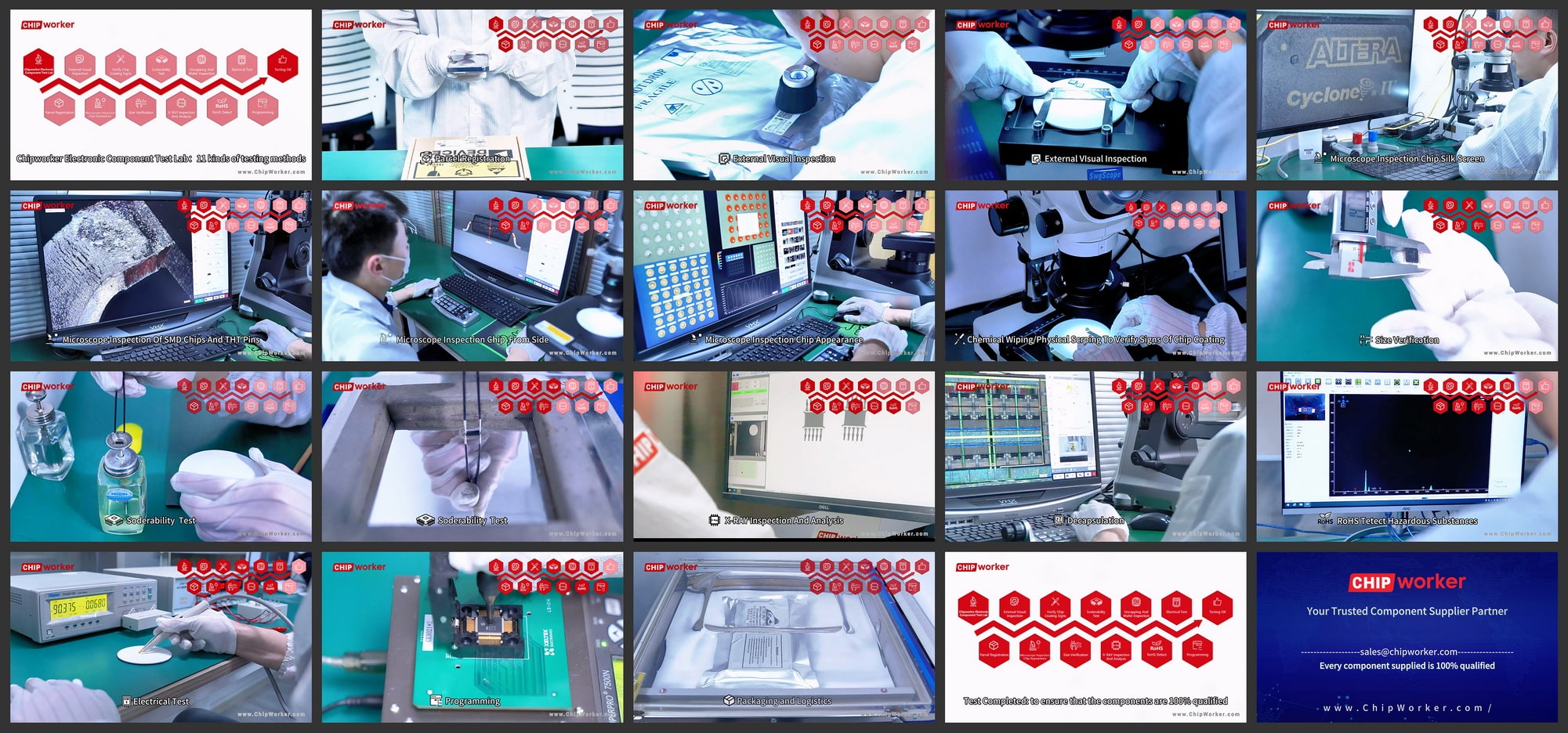

ChipWorker has an advanced component testing laboratory with an area of 500 m², based on big data on testing 3,000,000+ chips and checking for counterfeiting of thousands of branded components. Engineers will inspect, measure, inspect and test electronic components, from the outer packaging to the inner, and issue authoritative test reports to ensure that the components meet the highest standards, thereby ensuring that the components are sold as 100% new and original, and ensuring the safety of your supply chain.

The laboratory is equipped with an advanced SEAMARK X-ray detector and a KEYENCE 3D electron microscope, which allow X-ray fluoroscopy and magnification testing of chip plates and internal terminals. The laboratory implements strict CMA testing standards to help customers get rid of the need to buy refurbished and substandard products.

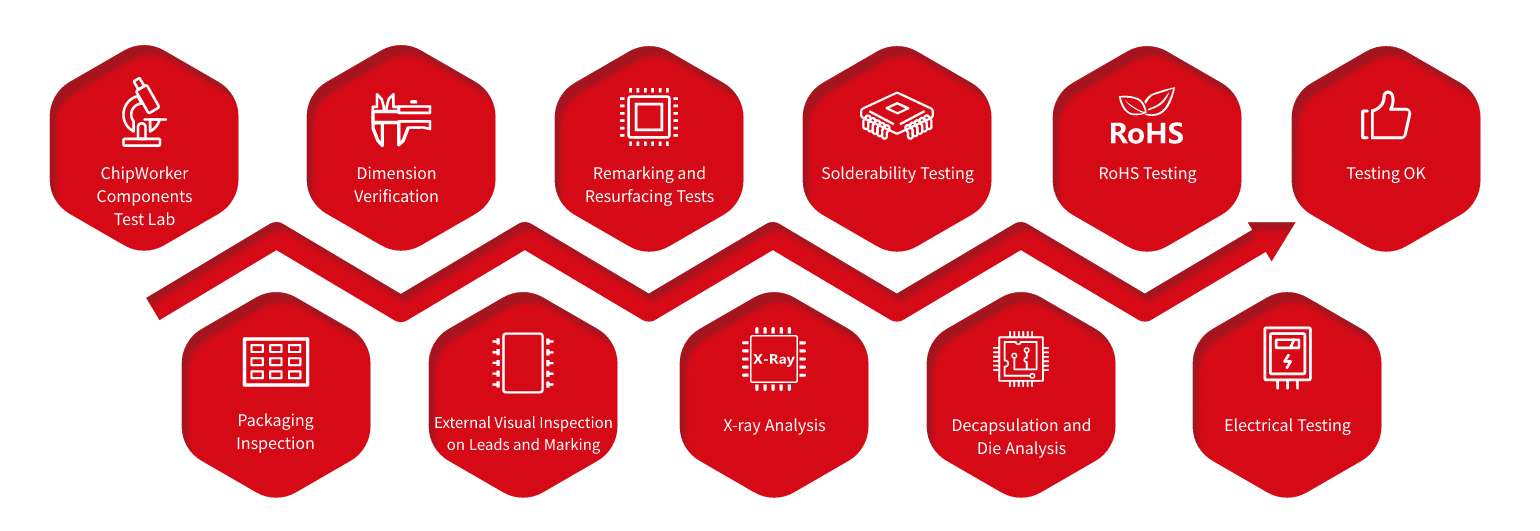

Dimension Verification

External Visual Inspection on Leads and Marking

Remarking and Resurfacing Tests

X-ray Analysis

Solderability Testing

Decapsulation and Die Analysis

RoHS Testing

Electrical Testing